A VP employee scans a completed beam for shipment.

| Company: | VP Buildings, Inc. (www.vp.com) |

| Application: | Product tracking system developed with Data Net's Co-Log®/Open software |

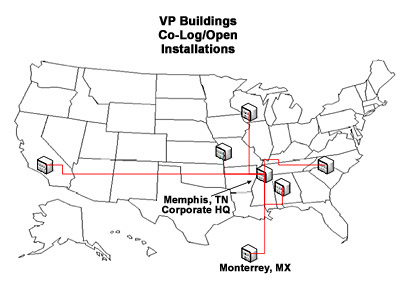

| Environment: | Multiple manufacturing facilities in the US and Mexico |

Benefits:

Company Overview: VP Buildings (wholly-owned subsidiary of Grupo IMSA, S.A. de C.V.)

VP Buildings is a world leader in the steel systems construction industry. VP Buildings designs and manufactures steel buildings ranging from small warehouses to entire office buildings. With a workforce of over 1600 in US and sister company's Mexican plants, VP manufactures building parts two shifts, six days per week. Finished products are shipped directly to customers and job sites.

Data Collection: The Need

Prior to 2001, VP had been using a 900 MHz RF mobile data collection system with limited communication to the legacy UNIX-based ERP system. Transactions on the handheld terminals were limited and modifications to the terminal emulation user interface were costly. With the forthcoming systems and database changes and increasing warehouse activity, VP needed a cost-effective solution that would allow for easy modification without having to be dependant upon a consultant..

Data Net's Solution

VP Buildings' migration to a custom Windows-based ERP system allowed them the flexibility to develop their own data collection routines and host update models without the costly, arduous task of writing emulation programs. "We looked at multiple off the shelf applications for our data collection system. Data Net's Co-Log/Open not only provided us with an economical, scalable tool, but also an application which is quite easy for developers and non-developers to write custom datacollection applications". — Walt Wieners, Manufacturing Systems Manager, VP Buildings, Inc.

A VP employee scans a completed beam for shipment.

Communications with the corporate offices in Memphis, Tennessee are achieved with T1 connections in each facility. Data collection activities are conducted over a Symbol 802.11b wireless infrastructure with Data Net's DNT 550 RF terminals. VP employees print and apply bar-coded labels to the finished product upon completion. Each label contains a unique piece identifier barcode. Once scanned, production completion is automatically recorded. Part characteristics are also readily available for more accurate packing lists and bills of lading.

By virtue of Co-Log/Open's flexibility, VP is able to quickly modify handheld terminal transaction sets and menus, depending on the needs of each facility. For example, at the sister company's Mexico facilities operator prompting is in Spanish.

"Co-Log/Open provides us with the means to allow each facility to operate independently, in terms terminal user interfaces and the types of transactions required". —Walt Wieners, Manufacturing Systems Manager, VP Buildings, Inc.

A shipping employee verifies an outbound shipment.

Benefits

VP Buildings' initial intention was to simply replace the aging 900 MHz system with a modern data collection solution to address only the needs of the shipping department. Eventually, the system was expanded to include the manufacturing process.

Installation of the Co-Log/Open system in late 2002 resulted in the following returns on investment for the company assoon as early 2003: